Difference between lithium battery and lead-acid battery

Upload Time:

Dec 16, 2023

What is the difference between lithium battery and lead battery? Although they are all batteries, the biggest difference is that the differences in manufacturing materials and discharge performance lead to changes in application fields.

What is the difference between lithium battery and lead battery? Although they are all batteries, the biggest difference is that the differences in manufacturing materials and discharge performance lead to changes in application fields.

1. Material difference between lithium battery and lead-acid battery

Lithium battery manufacturing materials:

Lithium batteries include polymer lithium batteries, lithium cobalt acid batteries, ternary lithium batteries and lithium phosphate batteries. They manufacture cathode materials, cathode materials, diaphragms, electrolytes and other main materials.

(1) The most commonly used cathode materials are lithium drill, lithium oxide, lithium iron phosphate and ternary materials (nickel drilled through manganese polymer). The quality of cathode material directly affects the performance of lithium-ion battery, and because its cost directly determines the cost of battery, the quality of cathode material is 3:1-4:1.

(2) Among cathode materials, at present, cathode materials are mainly natural graphite and artificial graphite. The cathode materials under discussion include nitrides, PAS, tin oxide, tin alloys, nano cathode materials and some other intermetallic compounds. Cathode material, one of the four main components of lithium battery, plays an important role in improving battery capacity and cycle performance. It is an indispensable part of lithium battery industry.

(3) The market-oriented diaphragm materials are mainly polyethylene (PE) and polypropylene (PP) based polyolefin diaphragms. In the lithium battery structure, the diaphragm is one of the core internal components. The performance of the diaphragm determines the interface structure and internal resistance of the battery, which directly affects the capacity, cycle and safety performance of the battery. The diaphragm with good performance plays an important role in improving the comprehensive performance of the battery.

(4) Electrolytes are generally high-purity organic solvents, electrolyte lithium salts, necessary additives and other raw materials, which are mixed in a certain proportion under specific conditions. The electrolyte conducts conductive ions between the positive and negative electrodes of the lithium-ion battery, and the lithium-ion battery provides the guarantee of high voltage, high power and other advantages.

Lead acid battery manufacturing materials

Composition of lead-acid battery: plate, diaphragm, shell, electrolyte, lead connecting strip, extreme heat, etc

(1) Positive and negative plates

Classification and composition: the bipolar plate and cathode plate are composed of lattice fence and active substances filled on it.

Function: during battery charging and discharging, the mutual conversion of electric energy and chemical energy is realized through the chemical reaction between the active substance on the board and sulfuric acid in the electrolyte.

Color separation: the active material on the anode plate is dark brown lead dioxide (PbO2); The active material in the cathode plate is spongy pure lead (PB), which is blue gray.

Function of Grid: accept active substances and form panels.

Plate group: in order to increase the capacity of the battery, please weld multiple positive and negative plates in parallel to form a positive and negative plate group.

Special requirements for installation: during installation, the anode and cathode plates are embedded with each other, and the partition plate is inserted in the middle. The number of cathode plates in each single cell is always one more than that of positive plates.

(2) Diaphragm

Function: in order to reduce the internal resistance and size of the battery, the anode and cathode plates inside the battery must be as close as possible. In order not to contact each other, a partition must be used between the anode plate and the cathode plate.

Material requirements: the diaphragm material must be porous and permeable, and the chemical properties must be stable. It has good acid resistance and oxidation resistance.

Material: commonly used partition materials include wood partition, microporous rubber, microporous plastic, glass fiber and paperboard.

Installation requirements: after installation, the surface with groove must face the bipolar plate.

(3) Housing

Function: used to hold electrolyte and plate group.

Material: made of materials with good acid resistance, heat resistance, shock resistance, insulation and constant mechanical properties.

Structural features: the shell is an integrated structure. The interior of the shell is divided into 3 or 6 single grids not connected with each other between the walls. There are extruded ribs on the floor and a group of plates are retained. The space between ribs is used to accumulate peeled active substances to prevent short circuit between plates. After the plate is installed into the shell, the upper part is sealed with a battery cover made of the same material as the shell. The battery cover has a value hole on the top of each single grid to add electrolyte and distilled water. It can also be used to determine the height of electrolyte level and measure the relative density of electrolyte.

(4) Electrolyte

Function: during the electrochemical reaction of charging and discharging (the conversion process of electric and chemical energy), ions play a conductive role and participate in the chemical reaction.

Composition: it is made with pure sulfuric acid and distilled water in a certain proportion, and its density is generally 1.24 ~ 1.30g/ml.

Special precautions: the purity of electrolyte is an important factor affecting the performance and service life of battery.

2. Difference of discharge performance between lithium battery and lead-acid battery

(1) Under the low temperature environment of the battery, the lithium battery is resistant to low temperature and the discharge performance is much better than that of the lead shaft.

(2) Under the cycle life, lithium battery is about twice that of lead-acid battery.

(3) Under the working voltage, the lithium battery is 3.7V and the lead-acid battery is 2.0V, and the discharge platform is higher than that of the lead-acid battery.

(4) Under the battery energy density, the lithium battery is much higher than the lead axis.

(5) Lithium battery is lighter under the same capacity and voltage, and is more flexible than lead-acid battery in size and shape.

Nevertheless, lead-acid batteries occupy a solid position in most existing fields and some emerging application fields through many advantages, such as high current discharge performance, stable voltage characteristics, wide temperature coverage range, high-capacity single battery capacity, high safety, rich raw materials and recycling, low price and so on.

3.Differences between lithium battery and lead battery in application

Lithium batteries can be customized more flexibly in terms of energy density, size and shape, so they are more inclined to lightweight intelligent devices in application fields, such as intelligent wearable 3C products, portable mobile power supply, etc.

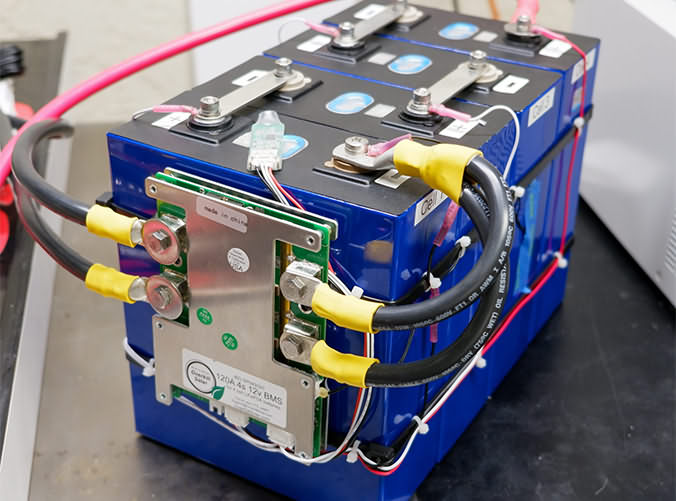

Lead acid batteries have single shape, large monomer and large volume. Most of them are used for energy storage devices, which are easy to carry, but some devices can not continue to use AC power supply.

Relevant News